DMC PRO

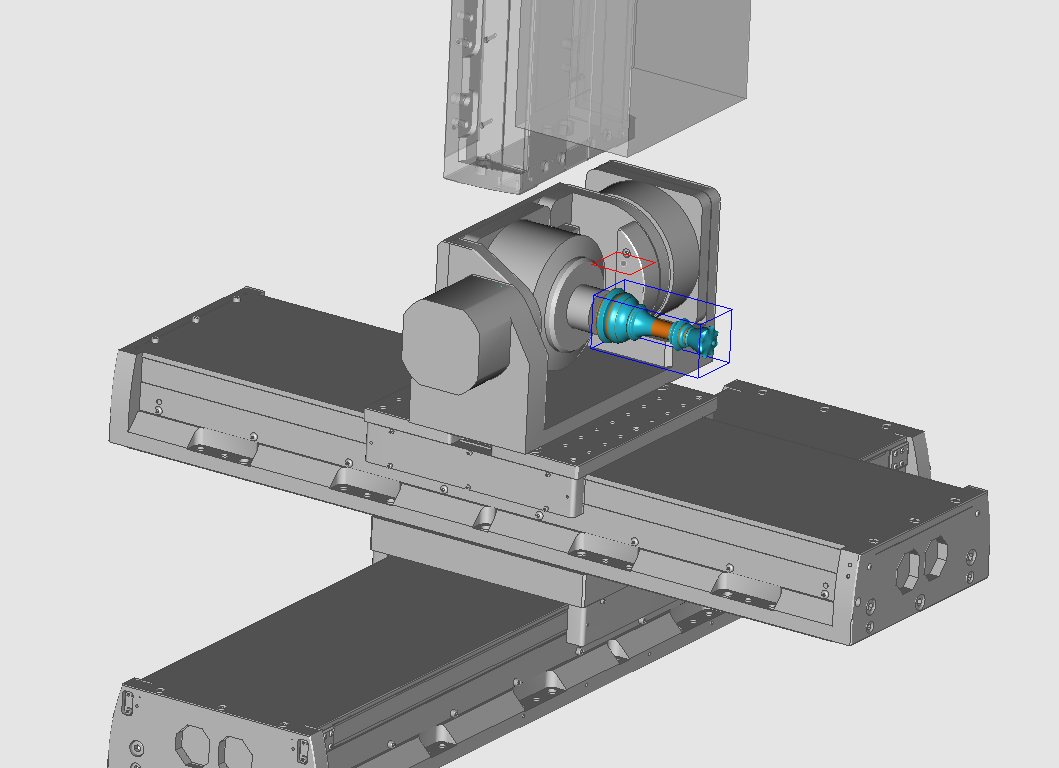

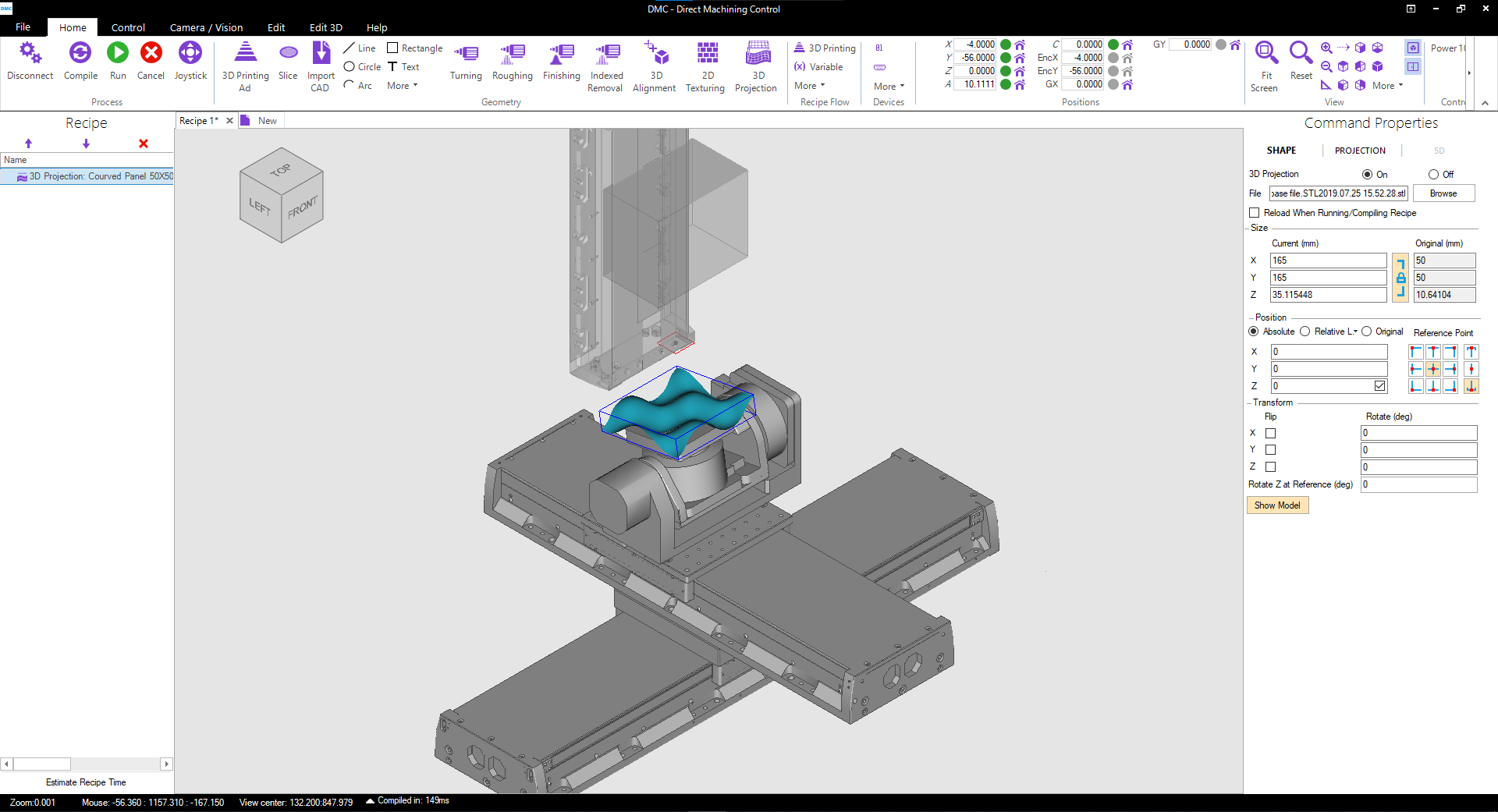

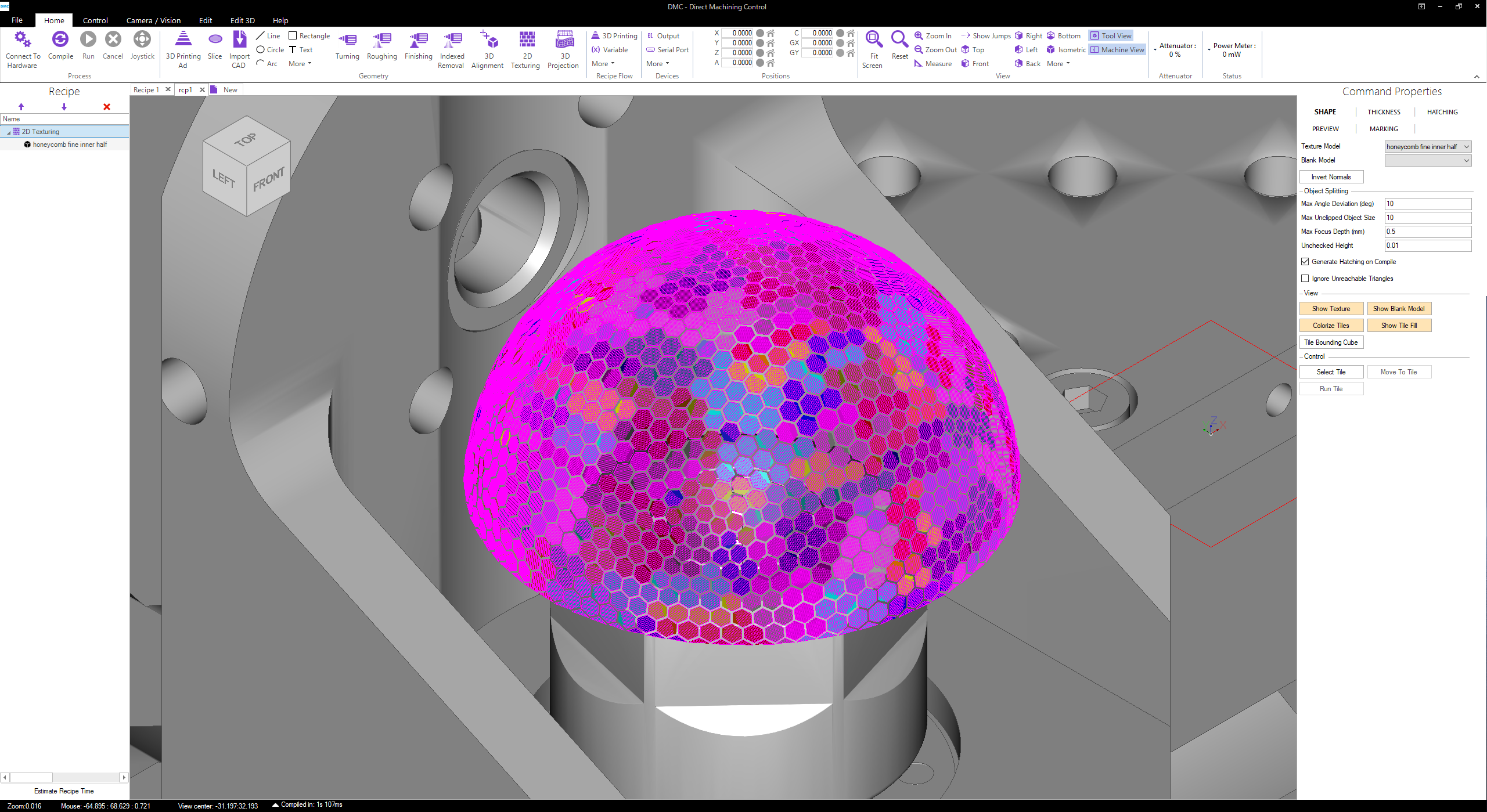

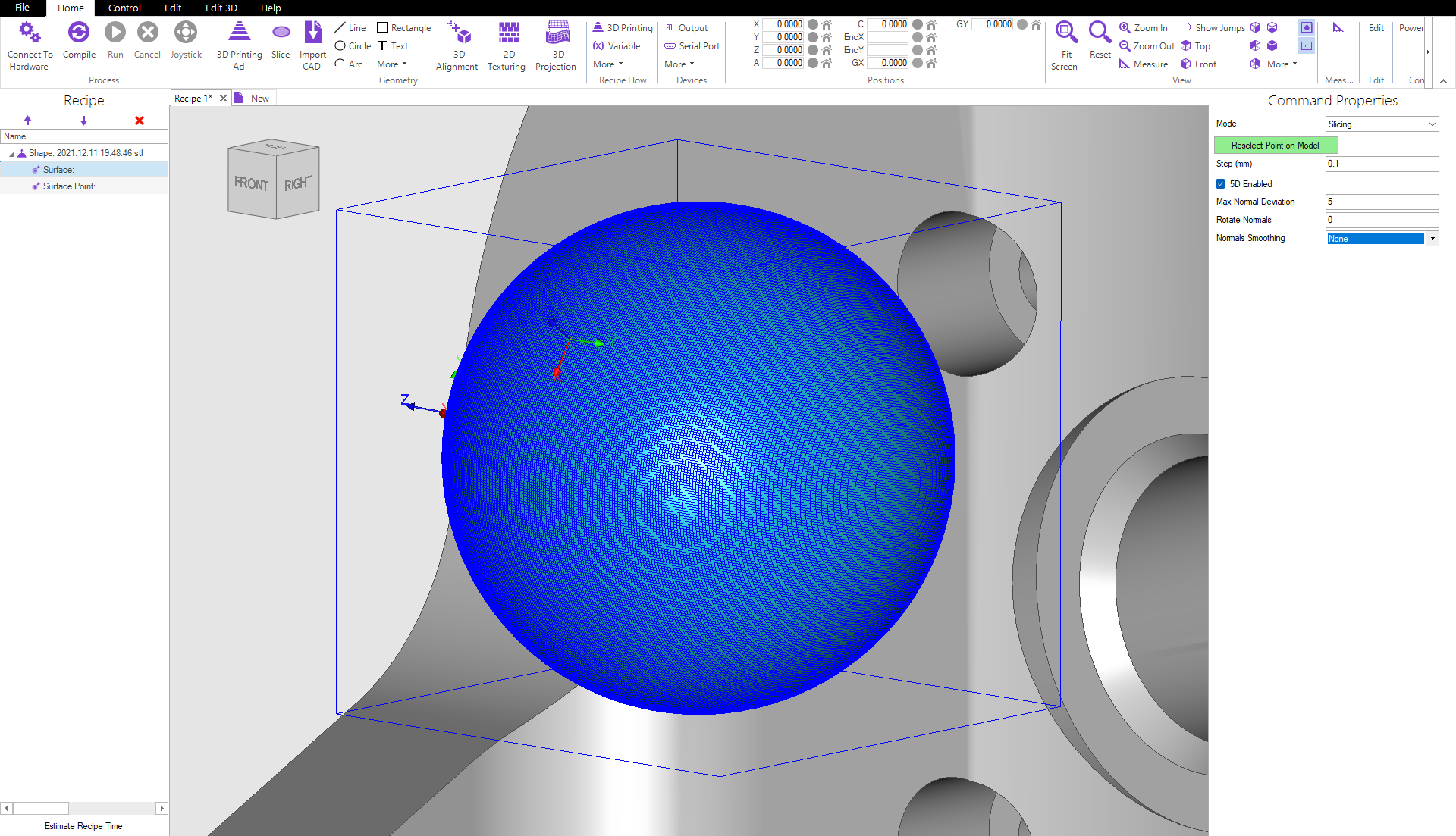

DMC PRO is a fully featured software to prepare and control your laser machining processes. Control laser, galvos, stages, cameras, etc. from single software.

DMC OEM

DMC OEM is a tailor made version to fit your laser machining application and your laser machine. Add new HMI, features and hardware to control your machine fully.